CGDB Submitting Data

CGDB

Related Resources

Submitting Data to CGDB

The following are specific requirements for different product types.

Data format

During 2018 we will be using a text format for submitting data of diffuse samples that are characterized with direct-direct and direct-diffuse spectral properties, the definition is available in the Related download section below. The format is an extension based on the current IGDB format. The main difference between the two formats is the number of data columns as well as fields for AERC ID and extrapolation method. Examples of how files look for different products are available in the file section at the bottom of this page.

Venetian Blind Slats

Venetian blinds (horizontal louvered shades) can be simulated in WINDOW using the ISO 15099 model combined with the multi-layer matrix method (Klems 1994). These methods require optical properties of slat material as follows:

- Both front and back surfaces are diffuse (e.g. painted). Unfinished aluminum is typically too specular (mirror-like) to work with the model.

- The geometry has no more than a single curve (flat is fine, but no "S" or "W" like shapes).

- The slats are thin compared to the gap between the slats. Typical geometries are less than 1 mm thickness to a 15 mm gap between slats and that is fine.

- The perforation used to suspend the blinds can be ignored.

Note: Experiment with the WINDOW 7 shade layer interface for Venetian blinds to see what geometries are possible and what information is required. If your product meets those requirements it can be included in the CGDB as a shade material and shade layer.

See the subpage in the menu to the left to find complete documentation of measurement, submission, and simulation.

Shade Screens and Cellular Shades (Fabric Type Materials)

- The fabric is thin (i.e., less than 1 mm).

- The pattern scale should be no more than 2 mm or much larger than 25 mm.

- The material is effectively flat.

- If the product consists of more than 1 fabric, each fabric needs to be measured individually (e.g., for a cellular shade, front, back, and glue line could each be a separate fabric)

- If the fabric has different front and back properties, the front should be clearly marked. The front surface corresponds to the exterior surface, i.e. the surface seen from the outside of the window.

Perforated Screens

- The screen material is thin.

- The screen has a regular pattern of circles or rectangles.

- The unperforated material is homogeneous.

- The material is effectively flat.

Peer Review

Submitted data are subject to peer review. Members of the peer review group will get an email notification that the peer review files are ready for review. The schedule below gives the start and end time for the peer review, defining a time window to provide comments for each release cycle.

To join the peer review group please send an email to [email protected].

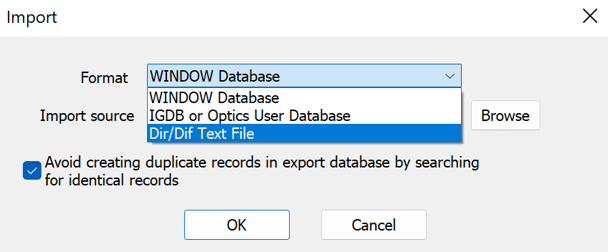

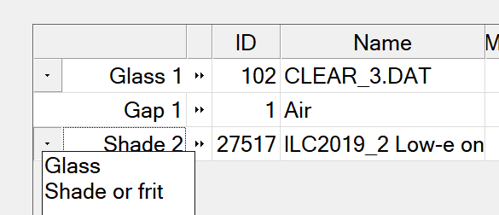

There is a wide range of different products in the CGDB which leads to multiple different steps to review the data. All data is shared in a WINDOW database so that the peer reviewer can interact with the the data using WINDOW. Furthermore the peer review comes with PDF documents with tabulated data showing integrated values for added Shade Materials, as well as graphs of the spectral data. However, Shade Layers that are built from materials, e.g. Venetian Blinds layers, are not present in the spectral data graphs and tables, only the slat material properties show up there. WINDOW has to be used to review the geometry of such layers.

CGDB Schedule

There are currently four CGDB releases per year. Data submitters should follow the schedule below for their data submission. Due to the short processing time, we will no longer accept more than 40 submissions or requests for modification/change from each manufacturer, in each cycle.

| Release Number | Submission Deadline | Data Goes to Peer Review | End of Peer Review | Release Date |

|---|---|---|---|---|

| 1 | 1/21 | 2/14 | 3/7 | 4/1 |

| 2 | 4/21 | 5/14 | 6/7 | 7/1 |

| 3 | 7/21 | 8/14 | 9/7 | 10/1 |

| 4 | 10/21 | 11/14 | 12/7 | 1/8 |

Submitting Data

LBNL is working on measurement procedures for different scattering products. After the publication of measurement procedure(s), an inter-laboratory comparison (ILC) will be conducted. The ILC is expected to be completed, and a full report published, within a year of its commencement. Upon completion of a successful ILC, with at least 1 commercial laboratory showing competence, commercial measurement of scattering systems will be approved.

Currently, LBNL is measuring optical properties of scattering products for a number of different materials and product types. Please send your request with completed submission form that is available from the Related downloads area below. The file has a file version number in it so you can see if it has changed since you last used it. Please contact [email protected] for a quote, lead time, and shipping address of your samples.