Dynamic Glazings and Advanced Coatings

Low emittance and solar control coatings for increased building energy efficiency

Advanced coatings selectively admit visible light and reject the thermal infrared.

Advanced coatings selectively admit visible light and reject the thermal infrared.

Switchable, dynamic coatings on glass or films have properties that are passively or actively controlled to modulate admission of light and heat. In collaboration with industry, Berkeley Lab material scientists continue to improve thin-film coatings and switchable device properties, manufacturability, and durability.

Read on to learn about technologies involved in creating dynamic glazings and advanced coatings for windows.

Related Technologies

Changing the World

to develop Low-E windows

Low-E windows – featuring an energy-saving technology developed through Berkeley Lab research – are now found in 80% of homes and 50% of buildings in the United States.

Window innovations we developed in collaboration with industry are cutting energy cost for American families, businesses, institutions, and governments every year. With funding from the Energy Department, Berkeley Lab has developed technologies that help prevent energy from escaping out of windows.

Lab researchers pioneered new energy-efficient windows, design tools, and window-rating systems, and then worked closely with window manufacturers and the building industry to achieve a greater than 80% market share of windows incorporating Low-emissive (Low-E) coatings in the residential sector, and more than 50% in the commercial sector.

Technology Platform

Low-E coatings have evolved into a “technology platform” on which new generations of innovative window designs are being based. Berkeley Lab continues to create innovative window technologies with practical applications in collaboration with industry.

Berkeley Lab researchers developed early design concepts and prototypes for "superwindows"— triple-paned windows with two low-E coatings and krypton gas fill—that actually insulate better than a wall. Lab researchers also have worked on highly-insulating aerogel windows and vacuum windows, both of which are still in the research and development phases. With Berkeley Lab leading the way, the efficient window of the future will be part of smart building systems, dynamically managing sunlight, view, and glare.

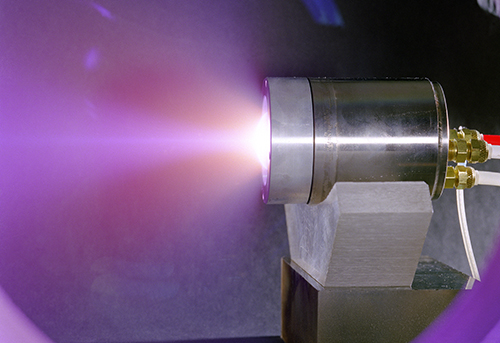

Advanced Sputtering - Applying a Film to Glass

In the high-tech world of advanced coatings, "sputtering" is a high-speed, high-volume process where superfast ions hit a metal target and dislodge miniscule particles that in turn coat a thin film over cutting-edge products like architectural glass, large-screen televisions and computer displays.

Berkeley Lab scientists are applying this method to low-e glass to further improve the product and save money. Adopting energy-saving coated glass in commercial and residential arenas is a rapidly advancing field that needs the science and data to support it.

Glassmakers use the sputtering to coat glass. During the coating process, argon gas is placed in a vacuum chamber and is ionized (gets a charge) so that magnetic fields can drive the argon atoms at high speed against the rotating sputtering target within a chamber. The argon atoms knock material loose from the sputtering target. This process occurs as a large piece of glass passes through the vacuum chamber. The loose material coats the glass. The glass coating is built up in layers by moving the glass back and forth.

Photospectrometry - Measuring Light

Photospectrometry is the quantitative measurement of the reflection or transmission properties of a material as a function of wavelength.

At Berkeley Lab we are at the forefront of utilizing this science to save energy and money in windows research.

We use photometers, known as spectrophotometers, that can measure a light beam's intensity as a function of its color (wavelength). With this information we are able to assess the heat and light coming in through a window and make adjustments to improve energy efficiency.

Transparent Conductive Oxides, Low-emissivity Glazings - Reflecting Heat

Transparent conductive oxides have high optical transmission at visible wavelengths and electrical conductivity close to that of metals. They also reflect near infrared and infrared (i.e., heat) wavelengths, and are used in products ranging from energy efficient low-e windows to photovoltaics.

Berkeley Lab teams are at the cutting edge of this research, inspiring industry to take the bold next steps.

Chromogenic Materials

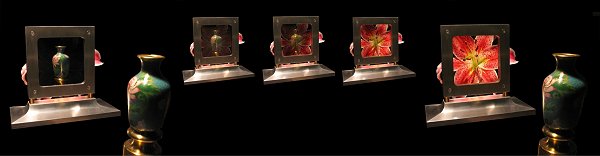

Glazing materials that selectively control the spectral aspect of radiation are now commonplace. Low-emittance coatings suppress infrared radiation transfer thereby imparting additional thermal insulation. Modified low-emittance coatings can also reject unwanted heat gain due to solar infrared. Additional energy savings result with dynamic control over the spectral characteristics of the glazing. There are a variety of technologies that can produce the desired effect.

The switchable-mirrors technology was developed by Tom Richardson and Jonathan Slack of the Energy Technologies Area at Berkeley Lab. By using transition metals rather than the rare earth metals used in the first metal-hydride switchable mirrors, Richardson and Slack were able to lower the cost and simplify the manufacturing process. Energy performance is improved as well, because the new windows can reflect or transmit both visible and infrared light. Besides windows for offices and homes, possible applications include automobile sunroofs, signs and displays, aircraft windows, and spacecraft.

See the mirror windows in action on YouTube.

Electrochromics

Considered to be the most suitable chromogenic technology for energy control in buildings, electrochromics are the subject of intensive research. Electrochromic materials undergo a reversible change in optical properties upon injection of light ions. Typically they consist of two electrodes separated by an ion conductor. Transparent conductors form the contacts. We have an active research program focusing on complementary counterelectrodes in lithium-ion systems. Association with the Berkeley Electrochemical Research Center provides a constant flow of new ideas for materials.

Measurement of optical properties is a specialty, and we have an extensive library of optical indices of electrochromic materials. Realistic images generated by Radiance have been used to visualize an electrochromic office and determine light levels under various conditions. DOE also supports an Electrochromics Initiative whose purpose is to accelerate the development of a window product.

Photochromics

As the name implies, these materials darken under the direct action of sunlight. They are not considered as versatile as electrochromics because they cannot be manually controlled and because optimum energy performance requires consideration of temperature conditions as well as solar radiation. For example, a photochromic window may darken on a cold sunny day when more solar heat gain is desirable. They are used widely for automatically darkening sunglasses as shown at corning.com. This is also an illustration about how our primary goal is to assist industry in developing new products.

Thermochromics

As photochromics respond primarily to light, thermotropics respond to heat. Again this is not as versatile a response as electrochromics. Daylight or view may have a higher priority for the occupant, at least temporarily, than reduction in solar gain.

Related Links:

Principal Investigator(s)

Andre Anders

Facilities

- Plasma Applications Laboratory

- Materials Characterization

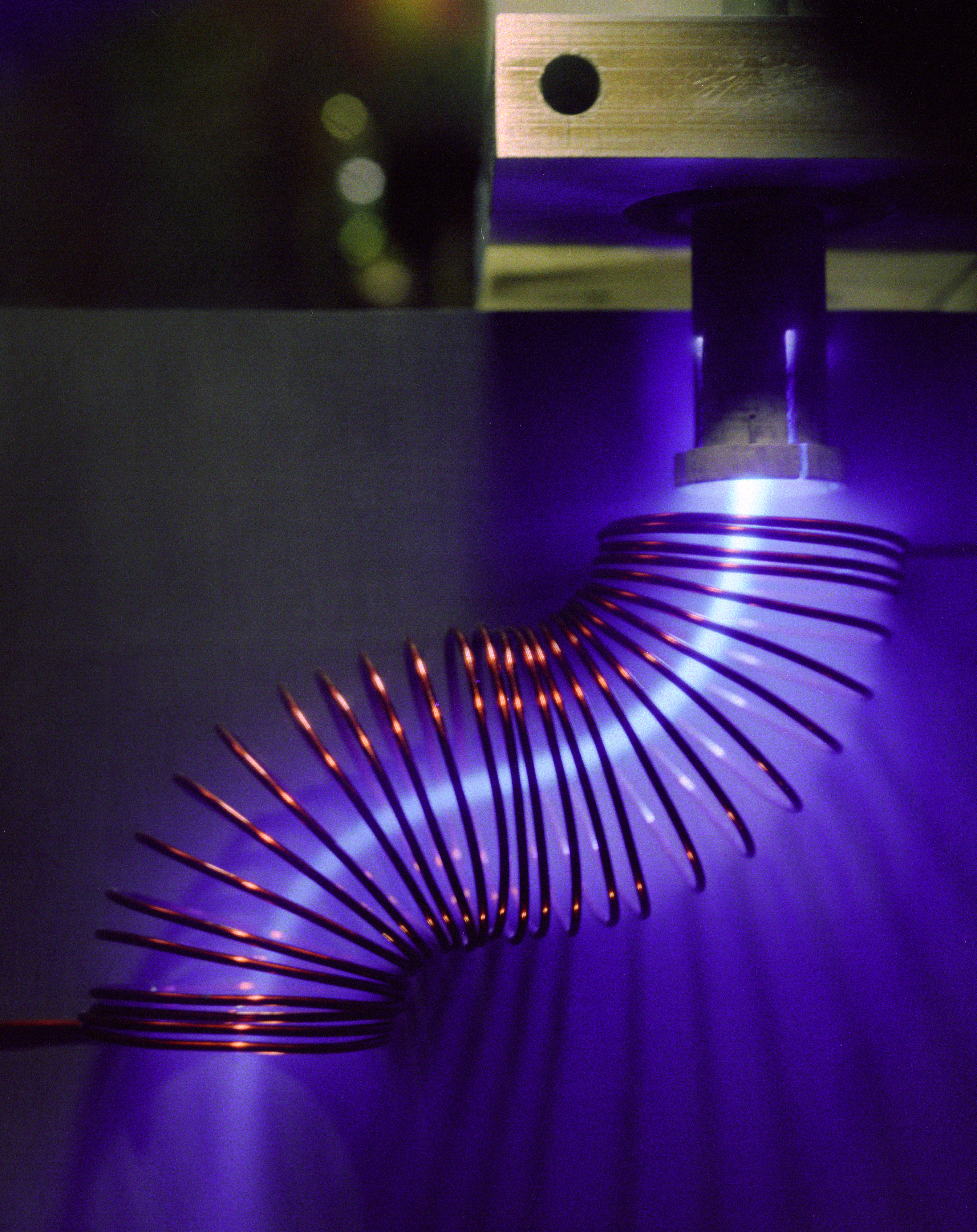

Filtered Cathodic Arc Deposition

Dynamic windows have a potential to better meet the demands of energy savings and comfort than static windows because they can adjust/optimize VIS-IR transmission depending on conditions and needs.

There is huge potential to save energy and money.

Researchers at Berkeley Lab and the Department of Energy are working to provide data and support to government and industry to reduce the cost in materials and fabrication methods in order to provide much broader market penetration.

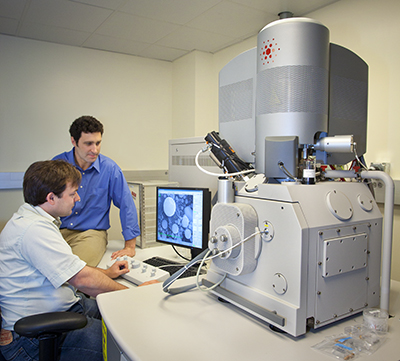

Ion Beam Analysis

Ion Beam Analysis (IBA) is an important family of modern analytical techniques involving the use of MeV ion beams to probe the composition and obtain elemental depth profiles in the near-surface layer of solids.

IBA is an active areas of research where Berkeley Lab scientists are using the latest techniques to detect elements in the sub-monolayer range.

Plasmonic Materials

Plasmonics is an exciting area of research because of the promise of new materials capable of:

- Remarkable optical properties such as confining and guiding light for sensor and computing applications

- Light trapping in photovoltaic cells or the possibility of modulating the transmittance of radiation in smart windows

- Plasmonic materials in the form of metallic multilayers

- Nanostructures embedded in dielectric matrices

- Exhibit tunable optical absorptions due to collective resonant oscillation of the free electrons in the conducting material as a response to the incoming illumination.

Our research is at the cutting edge of this science and we use the data to inform industry and policymakers as to best practices in this field.

The Windows Team at Berkeley Lab provides the foundational research needed to enable industry to move forward with innovative and exciting new products.