Window Reglazing Ratings

Window Reglazing Ratings

This page is intended to introduce the reglazing concept and to provide guidance on methodologies to simulate the thermal performance of a reglazed window. This information can be utilized as a basis for accurate direct comparison between reglazing strategies. Note that work is planned to develop a rating within the AERC framework - this page is interim guidance for use by those interested in performing this work.

Reglazing windows is a practical approach to enhancing the thermal performance of existing buildings, offering a cost-effective alternative to full window replacement. This process involves replacing old or inefficient glazing—the glass part of the window—with new, high-performance glass that better insulates and controls heat transfer. By upgrading to advanced glazing options, such as double-pane, triple-pane, or vacuum insulated glass (VIG) with low-emissivity (low-E) and solar control coatings, building owners can significantly reduce heat loss in the winter and heat gain in the summer. The result is not only improved energy efficiency and lower heating and cooling costs but also increased comfort for occupants and extended lifespan of the window frames by mitigating condensation and thermal stress. Reglazing is a compelling strategy in building retrofitting that aligns with energy conservation initiatives.

The National Fenestration Rating Council (NFRC) and the Attachments Energy Rating Council (AERC) are two organizations that develop rating systems to evaluate the energy performance of windows and window attachments. While both systems focus on promoting energy efficiency, they differ in their scope, metrics, and specific applications.

NFRC Rating System

The NFRC rating system is well-established and primarily focuses on evaluating the energy performance of new windows, doors, skylights, and window films. It provides standardized ratings that help consumers, builders, and policymakers make informed decisions about the energy efficiency of fenestration products. The NFRC evaluates key performance metrics such as:

- U-Factor: Measures the window’s rate of heat transfer and insulation ability. A lower U-Factor means better insulation.

- Solar Heat Gain Coefficient (SHGC): Indicates how much solar radiation is admitted through the window. A lower SHGC means less solar heat enters the building.

- Visible Transmittance (VT): Describes how much visible light passes through the window, contributing to daylighting

- Air Leakage: Measures the rate of air infiltration through the window.

AERC Rating System

The AERC focuses on the energy performance of window attachments, such as blinds, shades, and storm windows. These products are evaluated based on how they improve the energy performance of existing windows by enhancing insulation, controlling solar gain, and regulating airflow. AERC ratings provide a standardized way to assess the effectiveness of these attachments through metrics such as:

- U-Factor Improvement: How well the attachment improves the insulation of the window system.

- SHGC Improvement: The reduction in solar heat gain provided by the attachment.

- Energy Performance (EP): The overall impact on heating and cooling energy consumption when the attachment is used in conjunction with a window (residential only).

Both rating systems are crucial in helping homeowners, commercial building owners, and energy policymakers improve building performance and achieve energy savings. However, while the NFRC provides a baseline for the intrinsic energy efficiency of windows, the AERC highlights how additional products can further enhance this performance, offering flexibility in improving the energy efficiency of existing windows.

The purpose of this guidance document is to provide the technical rating procedures to determine the energy performance properties of fenestration retrofits that include the reglazing of existing window frames. The energy performance properties include overall heat transfer coefficient (U-factor), solar heat gain coefficient (SHGC), and visible transmittance (VT). To standardize performance comparisons between products, using one specific baseline window for all products being compared is recommended.

Baseline Frame:

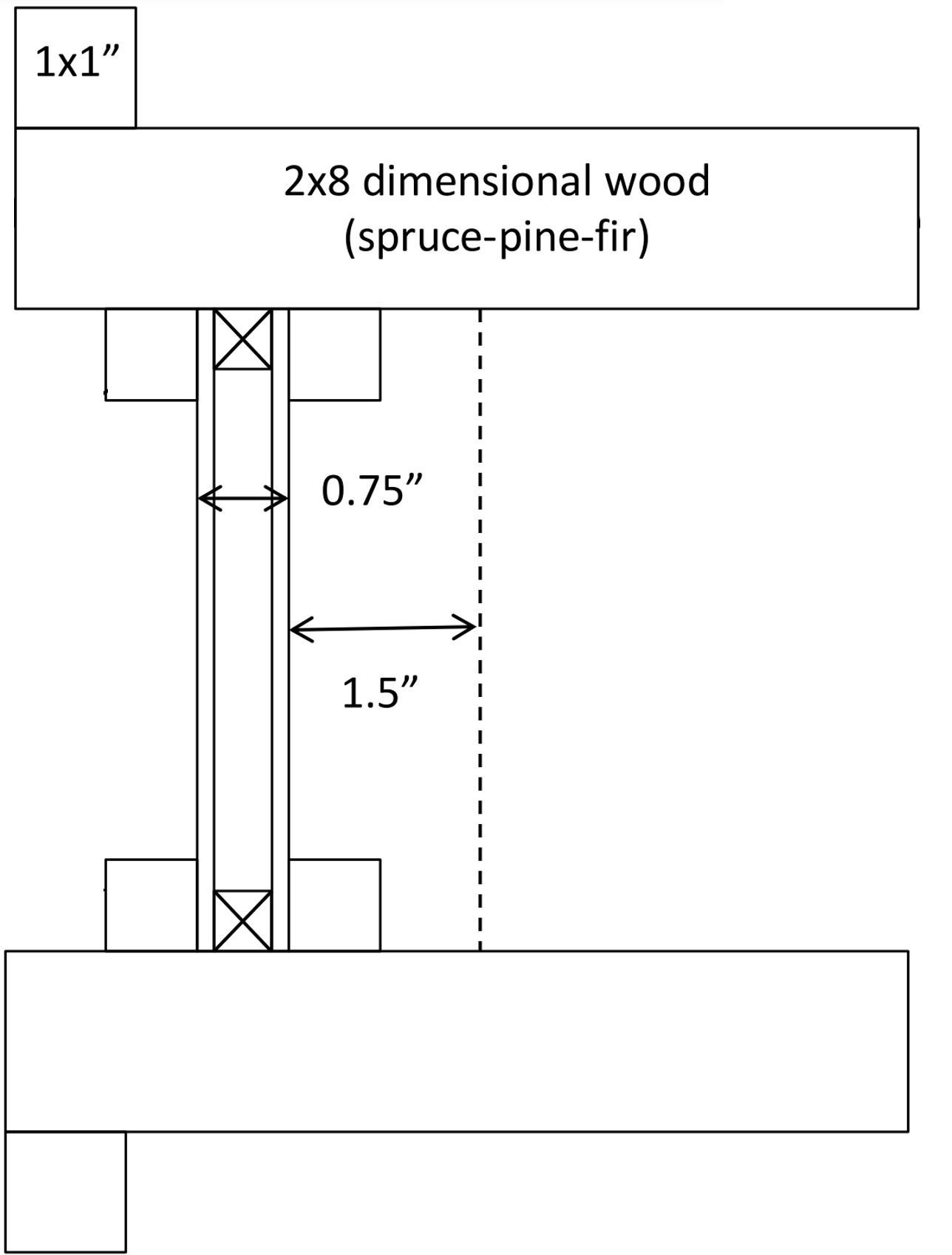

Utilizing standardized baseline frames enables consistency across performance comparisons.

AERC Baseline B

AERC Baseline B

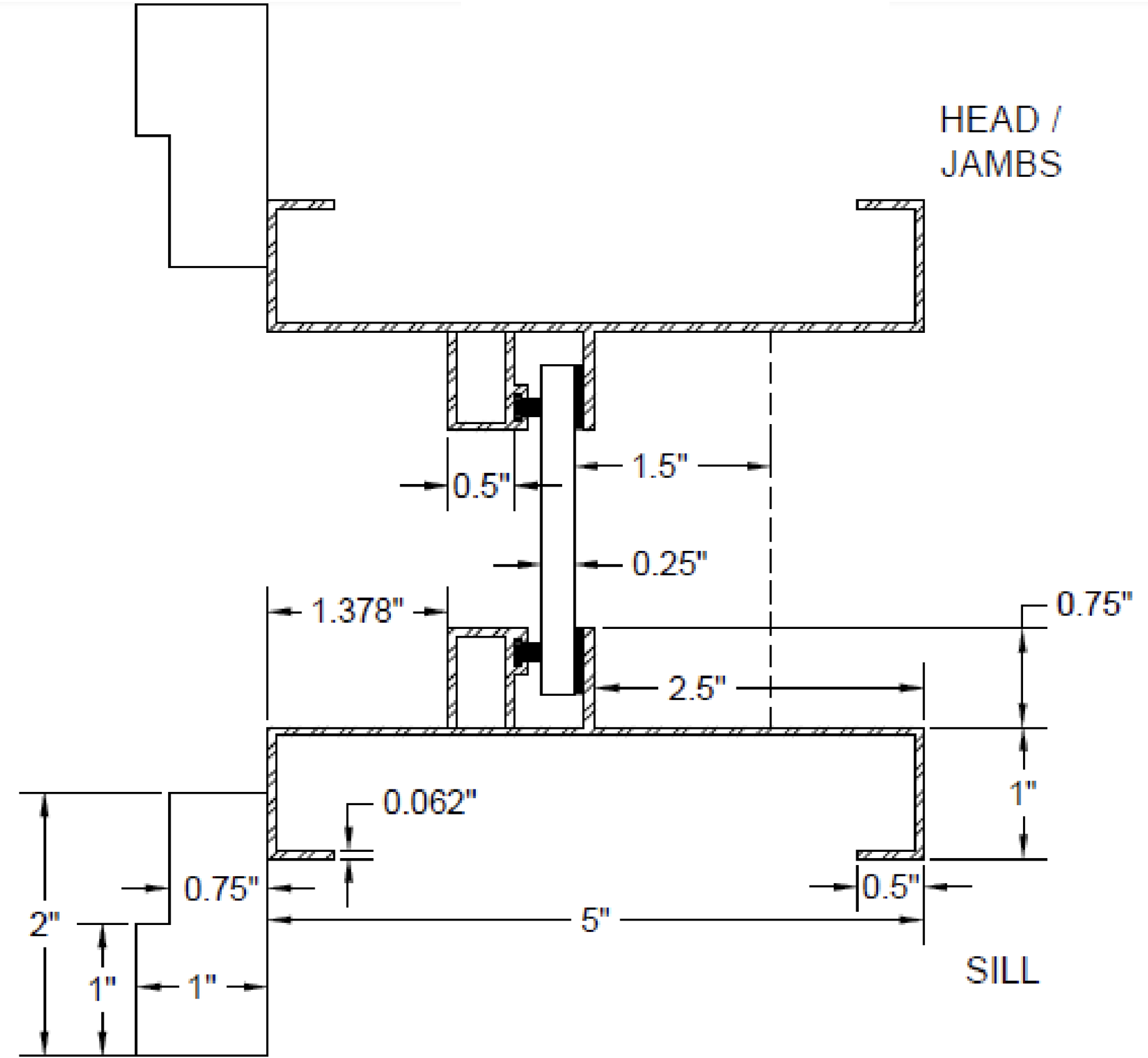

AERC Baseline D

AERC Baseline D

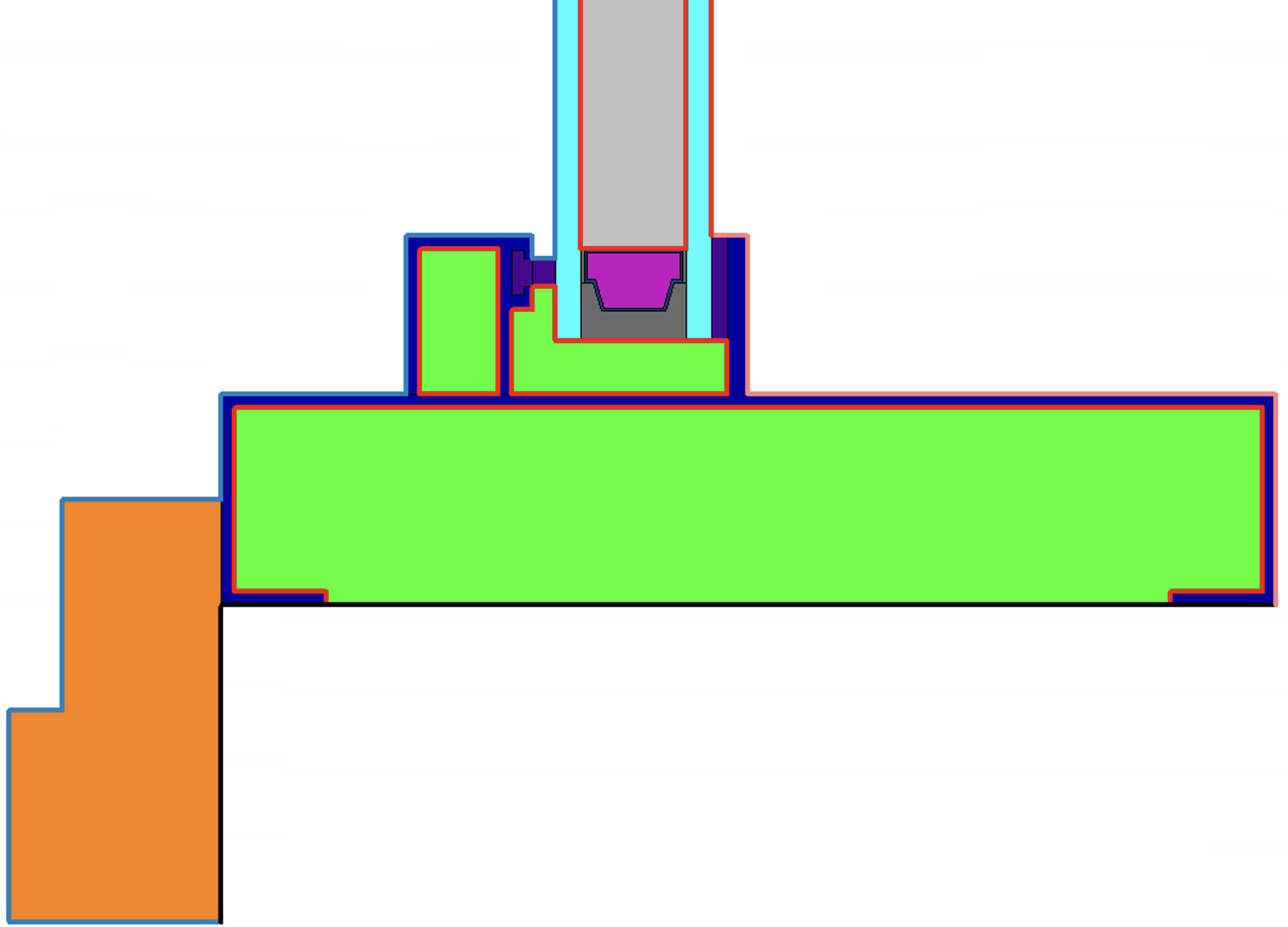

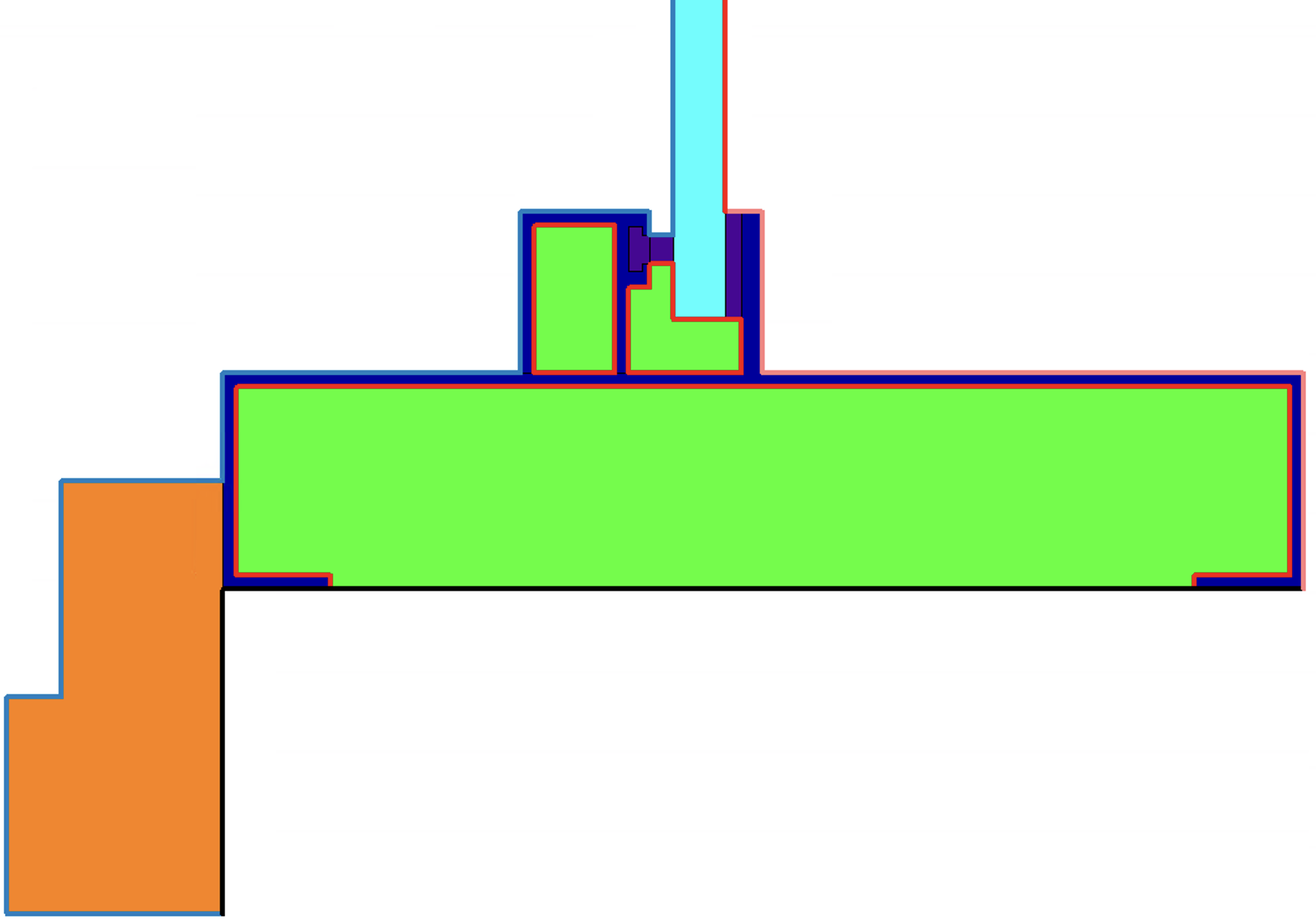

The baseline frames developed for AERC listed in Appendix A of AERC 1 provide a wide range of baseline frame types, and are recommended as the basis for reglazing analysis. Without specific building window knowledge we recommend to use Baseline B for residential style windows and Baseline D for commercial style windows. Window, Therm, and dxf files for each of the baseline windows can be downloaded by clicking the links below:

A. Nonmetal-framed, single pane, clear glass

B. Nonmetal-framed, double pane, clear glass (recommended baseline for residential)

C. Nonmetal-framed, double pane, low-E glass

D. Metal-framed, single pane, clear (recommended baseline for commercial)

E. Metal-framed, double pane, clear

F. Metal-framed, double pane, low-E

Where installation according to the dimensions in the drawings is precluded by physical constraints, the glazing plane may be modified to accommodate the reglazing product (modifying the glazing bead or adding a thermal cap over framing members). Any variations in the baseline dimensions should be recorded.

Non-rectangular products should be simulated as rectangular products over these baseline windows using the same materials and at the same standard size of 1200 mm width x 1500 mm height (exception: 1500 mm width x 1200 mm height for use with horizontal sliding storm windows).

U-factor Simulation Procedures:

- The U-factor should be calculated using the currently approved Lawrence Berkeley National Laboratory WINDOW and THERM software tools in accordance with AERC 1.3, AERC Simulation Manual, 2017.

- Default material and gas property libraries in the currently NFRC approved Lawrence Berkeley National Laboratory WINDOW and THERM software tools.

- Optical and thermophysical property data included in the latest published version of the IGDB and CGDB.

- Environmental and boundary conditions:

- Tinside = 21°C (69.8°F)

- ASHRAE / NFRC inside convection model in the currently approved Lawrence Berkeley National Laboratory WINDOW and THERM software tools

- Effective inside room temperature Trm,inside = Tinside

- Effective room emissivity = 1.0

- Toutside = -18°C (-0.4°F)

- ASHRAE / NFRC outside convection model with exterior wind speed = 5.5 m/s (convection coefficient hc=26 W/m2K)

- Effective sky temperature Tsky = Toutside

- Effective sky emissivity = 1.0

- Direct solar radiation Is = 0 W/m2

Solar Heat Gain Coefficient Simulation Procedures:

- The SHGC should be calculated for each individual product using the same procedures described for U-factor, but with modified boundary conditions of the following:

- Tinside = 24°C (75.2°F)

- Toutside = 32°C (89.6°F)

- ASHRAE / NFRC outside convection model with exterior wind speed = 2.75 m/s (convection coefficient hc=15 W/m2K)

-

Direct solar radiation Is = 783 W/m2

Visible Transmittance Simulation Procedures:

- The visible transmittance should be calculated for each individual product using the same procedures described for SHGC.

Operable Windows

An operable window is a type of window that can be opened and closed to allow for ventilation and airflow. Unlike fixed windows, which remain stationary, operable windows have mechanisms such as hinges, sliders, or cranks that enable them to move. Common types of operable windows include casement, sliding, awning, double-hung, and hopper windows. These windows offer flexibility for controlling indoor air circulation, light, and temperature, while also potentially serving as an emergency egress in certain building designs.

The AERC baseline window frames use a fixed (non-operable) frame as representative. We recommend approximating operable windows with the AERC fixed frames for thermal performance calculation at this time, but may add operable windows in the future development of a rating system.

Mullions and Muntins

A window mullion is a vertical or horizontal structural element that divides adjacent window panes or panels within a larger window frame. They provide support to the overall window structure, separating individual panes of glass while helping to distribute the weight and improve stability. While they may resemble window muntins, mullions are more structural, often holding larger sections of glass together in a window or door assembly.

A window muntin is a thin strip of material, typically wood, metal, or vinyl, that divides and holds individual panes of glass within a window sash. Traditionally, muntins were structural components used to hold smaller pieces of glass together to form a larger window, especially before the advent of larger, single-pane glass manufacturing. In modern windows, however, muntins are often purely decorative, giving the appearance of divided glass panes while being attached to a single large pane.

The AERC baseline window frames use a fixed (non-operable) frame as representative. There is currently no means to account for mullions or muntins in the simulations using these frames. We recommend ignoring the presence of mullions in the thermal performance calculation at this time, but may add mullions in the future development of a rating system.

Insect Screens and Solar Shades

A window screen is a mesh covering typically made from materials such as fiberglass or aluminum, designed to fit over the opening of a window. Its primary purpose is to allow fresh air and light to enter while preventing insects, debris, and other outdoor particles from coming inside. Window screens are commonly used in operable windows.

A window solar screen or shade is a specialized covering designed to block or reduce the amount of solar radiation that enters through a window, helping to control indoor temperatures and reduce glare. Solar screens are usually made from a mesh-like material that filters sunlight while still allowing visibility and airflow. Shades, on the other hand, are typically fabric-based and can be adjusted or rolled up to control light and privacy.

Existing screens and shades should be ignored for all comparison modeling of reglazing thermal performance. If solar screens or shades will be added as part of the reglazing effort then they should be simulated according to AERC 1 based on the shade type.

Air leakage

Air leakage in windows refers to the uncontrolled flow of air through gaps around the frames, impacting energy efficiency, comfort, and indoor air quality. It allows conditioned air to escape, forcing HVAC systems to work harder, increasing energy bills, and creating drafts that reduce thermal comfort. Air leakage can also introduce moisture, leading to condensation and structural damage, while compromising noise control and allowing outdoor pollutants to enter.

Air leakage can be a significant contributor to thermal transfer across a window, but is not accounted for in U-factor or SHGC ratings and is typically reported independently. AERC and NFRC have established protocols for test based air leakage ratings, but these are performed in laboratory settings. The ASTM E783-02 test method is designed for the in situ air leakage measurement of windows. We encourage this measurement to be done for windows that are planned for reglazing to help identify air leakage paths that should be sealed. Note that window air leakage is often not from the glass to frame connection, but at seals, pulley weight pockets, etc. The test should also be performed post retrofit to ensure any measures taken to reduce air leakage are successful.

Example 1

Double-pane clear aluminum window (AERC Baseline Window E) reglaze to double-pane low-E.

- Link to step-by-step tutorial (pdf)

- Link to WINDOW Database (zip)

- Link to Therm files (zip)

Example 2

Single-pane clear aluminum window (AERC Baseline Window D) reglaze to VIG, including a thermal cap to improve the thermal performance of the frame interior.

- Link to step-by-step tutorial (pdf)

- Link to WINDOW Database (zip)

- Link to Therm files (zip)